Overview of the Pulsar PTG1022H Parts Diagram

The Pulsar PTG1022H parts diagram provides a comprehensive visual guide to understanding the components of this walk-behind string trimmer; Available in the operator’s manual as a PDF, it details engine parts, trimmer head, and frame assembly, aiding in maintenance and repairs․

The Pulsar PTG1022H is a powerful and versatile walk-behind string trimmer designed for light-to-moderate brush cutting tasks․ Equipped with a robust 173cc OHV engine, it delivers reliable performance and durability․ This model features an adjustable trimmer head, allowing users to customize cutting widths for various yard tasks․ Its design emphasizes ease of use, with a recoil start system and an ergonomic handle for comfort during extended operations․ The PTG1022H is ideal for maintaining large outdoor spaces, offering a balance of power and maneuverability․ Additionally, the unit is backed by a comprehensive operator’s manual, which includes detailed maintenance instructions and troubleshooting guides to ensure optimal performance․ This makes it a practical choice for homeowners and outdoor enthusiasts seeking efficient yard maintenance solutions․

1․2 Importance of the Parts Diagram for Maintenance and Repair

The Pulsar PTG1022H parts diagram is essential for effective maintenance and repair, providing a detailed visual representation of the trimmer’s components․ By referencing the diagram, users can identify and locate specific parts, such as the engine, trimmer head, and chassis, ensuring accurate repairs․ This tool helps prevent errors during DIY maintenance, like replacing incorrect parts, which can lead to further damage or safety issues․ The diagram also aids in troubleshooting common problems, such as engine failure or poor performance, by allowing users to trace issues back to their source․ Regular maintenance, as outlined in the manual, relies heavily on this diagram for tasks like air filter cleaning and spark plug replacement․ Ultimately, it empowers users to maintain their equipment efficiently, extending its lifespan and ensuring optimal performance․

Key Components of the Pulsar PTG1022H

The PTG1022H features a robust 173cc OHV engine, a durable trimmer head with an auto-cutting system, and a lightweight yet sturdy frame for enhanced maneuverability and performance․

2․1 Engine Specifications (173cc OHV Engine)

The Pulsar PTG1022H is powered by a reliable 173cc OHV (Overhead Valve) engine, designed for efficient performance and durability․ This engine features a robust construction with a horizontal shaft, making it ideal for heavy-duty trimming tasks․ The OHV design ensures better fuel efficiency, reduced emissions, and quieter operation compared to traditional engines․ With a maximum power output tailored for consistent cutting performance, the engine is equipped with a recoil starter for easy ignition․ The 173cc displacement provides ample power to handle thick vegetation and demanding landscapes․ The engine’s components, as detailed in the parts diagram, include the cylinder, piston, crankshaft, and air filter, all working harmoniously to deliver reliable operation․ Regular maintenance, as outlined in the manual, ensures optimal engine longevity and performance․

2․2 Trimmer Head and Cutting System

The Pulsar PTG1022H features a durable and versatile trimmer head designed for efficient cutting performance․ The cutting system includes a dual-line feed mechanism, which ensures consistent line delivery and minimizes downtime․ The trimmer head is compatible with 0․095-inch diameter cutting line, ideal for tackling thick weeds and grass․ A bump feed system allows for easy line advancement by tapping the head on the ground․ Additionally, the trimmer is equipped with a metal blade option for heavier vegetation, providing versatility for various trimming tasks․ The cutting system’s components, as shown in the parts diagram, include the spool, line retainer, and cutting blade, all designed for durability and ease of maintenance․ This setup ensures reliable performance across different landscaping scenarios․

2․3 Frame and Chassis Design

The Pulsar PTG1022H features a robust and lightweight frame and chassis design, ensuring durability and ease of maneuverability․ Constructed from high-quality materials, the frame provides excellent structural integrity, supporting the engine and other components effectively․ The chassis is designed to absorb vibrations, reducing user fatigue during extended use․ Ergonomic handlebars with padded grips enhance comfort and control, while the overall layout ensures balanced weight distribution for stable operation․ The frame’s rust-resistant coating and sturdy build enable it to withstand demanding outdoor conditions․ This design prioritizes both performance and user comfort, making the PTG1022H suitable for a variety of trimming tasks․ The parts diagram highlights the frame’s components, emphasizing ease of assembly and maintenance․

2․4 Control and Safety Features

The Pulsar PTG1022H is equipped with intuitive control and safety features designed to enhance user experience and ensure safe operation․ The ergonomic throttle trigger provides smooth and precise control over the engine and cutting system․ A safety kill switch is integrated to immediately stop the engine in case of an emergency, preventing accidents․ The handlebar features a protective guard to prevent damage from impacts, while the cutting head is equipped with a safety shield to deflect debris․ These features work together to minimize risks and provide operators with confidence during use․ The parts diagram details these components, emphasizing their importance for both functionality and user protection․ Regular inspection of these features is recommended to maintain optimal performance and safety;

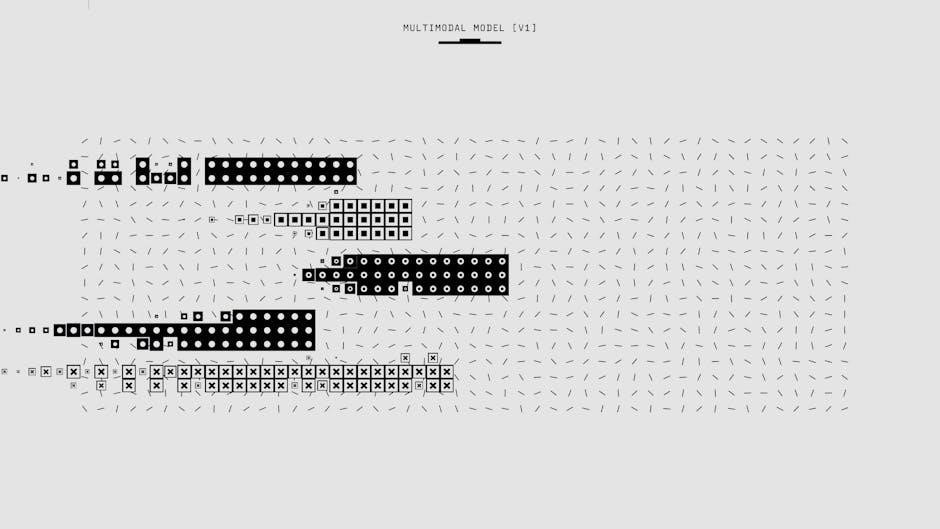

Understanding the Parts Diagram Layout

The Pulsar PTG1022H parts diagram provides a clear visual breakdown of components, organized by functional groups․ It uses numbered identifiers and color-coded sections for easy navigation and identification of parts, enabling users to locate and understand each component’s role and placement within the assembly․ This structured layout is essential for efficient maintenance, repair, and assembly, ensuring users can accurately identify and access necessary parts without confusion․ Regular reference to the diagram helps prevent errors and ensures proper reassembly․

3․1 Top-Level Assembly Breakdown

The Pulsar PTG1022H parts diagram begins with a top-level assembly breakdown, illustrating the main components of the trimmer in a hierarchical structure․ This section provides an overview of the major assemblies, such as the engine, handle, and cutting system, showing how they interconnect․ The diagram uses exploded views to visually separate large assemblies into smaller, manageable parts, making it easier to identify and locate components․ This high-level overview is essential for understanding the overall layout of the trimmer and how individual parts contribute to its functionality․ By referencing this section, users can quickly identify the primary systems and their relationships, facilitating maintenance and repair tasks․ The clear organization ensures that even complex assemblies are presented in an accessible manner․

3․2 Detailed Engine Parts and Their Functions

The Pulsar PTG1022H parts diagram provides a detailed breakdown of the engine components, highlighting each part’s role in the overall operation․ Key elements include the cylinder, piston, crankshaft, and carburetor, all working together to generate power․ The air filter and spark plug are also emphasized, as they are critical for proper combustion and engine performance․ The diagram labels each component, explaining its function, such as how the crankshaft converts reciprocating motion into rotational energy․ This level of detail helps users identify and understand each part’s importance, making maintenance and repairs more straightforward․ By referencing this section, users can pinpoint potential issues and ensure the engine runs efficiently․ The clear labeling and descriptions make it easier to diagnose and replace parts when necessary․

3․3 Trimmer Head and String Trimming Components

The trimmer head and string trimming components are essential for the PTG1022H’s cutting functionality․ The parts diagram details the cutting head assembly, which includes the spool, trimmer line, and spring․ These parts work together to feed and cut vegetation effectively․ The spool holds the trimmer line, while the spring ensures proper tension․ The diagram also highlights the cutting head gear, which drives the trimming operation․ Understanding these components helps users replace worn or damaged parts, such as the trimmer line, to maintain optimal performance․ The clear illustrations in the parts diagram make it easier to identify and service each component, ensuring efficient and accurate repairs․ This section is crucial for users looking to maintain or upgrade their trimmer’s cutting capabilities․

Operational Manual Highlights

The operational manual provides essential guidance for safe and effective use of the PTG1022H․ It includes key startup procedures, safety precautions, and assembly instructions for optimal performance․

4․1 Key Startup Steps for the PTG1022H

The operational manual outlines clear startup steps for the PTG1022H․ Begin by ensuring the fuel tank is filled with the recommended fuel mixture․ Next, check the cutting head for proper installation and tighten any loose parts using the parts diagram as a reference․ Prime the engine by pressing the primer bulb 3-5 times until it feels firm․ Move the choke to the “start” position and pull the starter cord gently until resistance is felt, then pull sharply to start the engine․ Allow the engine to warm up for a few seconds before adjusting the choke to the “run” position․ Always wear protective gear and ensure the area is clear of debris before operation․ Refer to the parts diagram for visual guidance on key components․

4․2 Safety Precautions and Guidelines

Before operating the PTG1022H, always wear protective gear, including gloves, safety goggles, and sturdy footwear; Ensure the area is clear of debris, children, and pets․ Avoid wearing loose clothing that could get caught in moving parts․ Never operate the trimmer near open flames or sparks, as it may emit flammable vapors․ Keep the machine well-maintained, referring to the parts diagram to ensure all components are secure and functioning properly․ Avoid overreaching or using excessive force, which could lead to loss of control․ If unfamiliar with any part, consult the manual or contact Pulsar support․ Always follow the recommended safety guidelines to minimize risks and ensure safe operation․ Regularly inspect the trimmer head and cutting system for damage or wear․

4․3 Assembly Instructions for New Users

Begin by carefully unpacking the PTG1022H and verifying all components against the parts diagram․ Attach the handle by aligning the clamp and tightening the bolts securely․ Next, assemble the trimmer head by threading the cutting string through the guide, ensuring it aligns with the arrow on the spool․ For the cutting blade, attach it to the gearbox shaft, tightening firmly․ Refer to the diagram to ensure proper orientation․ Finally, connect the throttle cable to the engine, making sure it moves smoothly․ Always wear gloves and safety goggles during assembly․ If unsure about any step, consult the manual or contact Pulsar support for assistance․ Proper assembly is critical for safe and efficient operation․

Maintenance and Adjustments

Regular maintenance ensures optimal performance․ Clean the air filter, check spark plug condition, and inspect the fuel system․ Adjustments may include tightening loose parts or lubricating moving components․

5․1 Air Cleaner Servicing and Replacement

The air cleaner is essential for ensuring clean air intake, which directly affects engine performance․ Regular servicing is recommended to prevent dust and debris buildup․

To service, remove the air cleaner cover and gently wash the filter with mild soap and water․ Allow it to dry completely before reinstalling․

Inspect the gasket for any signs of wear or damage and replace it if necessary․ If the filter is damaged or torn, replace it with a compatible part from the PTG1022H parts diagram․

Replacement is typically needed every 100 hours of use or as specified in the manual․ Proper maintenance ensures efficient engine operation and prevents premature wear․

5․2 Spark Plug Maintenance and Replacement

Spark plugs are critical for proper engine ignition and performance․ Regular maintenance ensures consistent combustion and prevents engine misfires․

Inspect the spark plug for fouling, wear, or gaps exceeding 0․030 inches․ Cleaning is not recommended; replacement is the best option․

To replace, locate the spark plug on the engine (refer to the PTG1022H parts diagram for exact location)․ Use a spark plug socket to remove the old plug and install a new one with the correct gap specification․

Tighten the spark plug to the recommended torque to avoid damage․ Replace every 100 operating hours or as indicated by performance issues․ Always use a spark tester to verify functionality after installation․

5․3 Fuel System Care and Recommendations

Proper maintenance of the fuel system is essential for optimal performance and longevity of the Pulsar PTG1022H․ Always use fresh, high-quality gasoline with an octane rating of 87 or higher, as specified in the manual․

Avoid using stale fuel, as it can lead to engine issues․ If the unit will be stored for an extended period, drain the fuel tank and let the engine run until it shuts off․

Inspect the fuel line and filter regularly for cracks, blockages, or contamination․ Clean or replace the fuel filter as needed to ensure proper flow․

Refer to the PTG1022H parts diagram to locate and identify fuel system components․ Regularly check for leaks around fuel line connections and tighten them if necessary․

These practices will help maintain fuel efficiency, reduce the risk of engine damage, and ensure reliable operation․

Troubleshooting Common Issues

This section provides guidance on identifying and resolving common problems with the Pulsar PTG1022H, such as engine startup issues, irregular operation, or vibration concerns․

6․1 Engine Fails to Start: Possible Causes

The engine failing to start can be due to several factors, as outlined in the Pulsar PTG1022H parts diagram․ Common issues include a clogged air filter, which restricts airflow, or a faulty spark plug that prevents proper ignition․ Additionally, stale or insufficient fuel, a blocked fuel line, or incorrect carburetor settings can disrupt the engine’s ability to start․ Users should also check for a malfunctioning ignition coil or a broken recoil starter․ It is essential to ensure the choke is in the correct position and that the fuel cap is venting properly․ Referencing the parts diagram can help locate these components for inspection and repair․ Always follow safety guidelines when diagnosing and addressing startup issues․

6․2 Engine Runs Erratically: Diagnostic Steps

If the engine runs erratically, it could indicate issues with the fuel system, air intake, or ignition components․ First, check the fuel for staleness or contamination, as this can disrupt combustion․ Ensure the air filter is clean and free of debris, as a dirty filter can cause uneven airflow․ Inspect the spark plug for proper gap spacing and cleanliness, as a fouled or worn-out spark plug can lead to misfires․ Additionally, verify that the carburetor is properly adjusted, as incorrect settings can cause erratic performance․ Consult the Pulsar PTG1022H parts diagram to locate these components and perform a systematic inspection․ Addressing these areas can help restore smooth engine operation․ Always follow safety guidelines during diagnostics․

6․3 Excessive Vibration and Poor Performance

Excessive vibration and poor performance in the Pulsar PTG1022H can result from imbalanced or damaged components․ First, inspect the cutting head and blade for damage or uneven wear, as this can disrupt operation․ Check the engine’s mounting bolts for tightness, as loose connections can cause vibration․ Additionally, ensure the drive shaft and trimmer head are properly aligned and free from debris․ Refer to the parts diagram to locate these components and perform a thorough inspection․ If vibration persists, consider balancing the blade or replacing worn-out parts․ Regular maintenance, such as lubricating moving parts and ensuring proper blade sharpness, can help prevent these issues․ Always consult the parts diagram for accurate repairs and adjustments․

Warranty and Support Information

The Pulsar PTG1022H is backed by a 2-year limited warranty covering manufacturing defects․ For support, contact Pulsar via phone, email, or their official website․ Refer to the parts diagram PDF for warranty details․

7․1 Warranty Coverage and Exclusions

The Pulsar PTG1022H is covered by a 2-year limited warranty from the date of purchase․ This warranty covers defects in materials and workmanship under normal use․ It includes repairs or replacements for faulty components, such as the engine, trimmer head, and chassis, when issues arise due to manufacturing defects․ However, the warranty excludes damage caused by misuse, improper maintenance, or accidental damage․ Wear and tear items, like cutting strings or air filters, are not covered․ To claim warranty service, users must provide proof of purchase and comply with diagnostic procedures outlined in the PTG1022H parts diagram PDF․ Unauthorized modifications or repairs void the warranty․ Always refer to the official manual for detailed terms and conditions․

7․2 Contacting Pulsar Support for Assistance

For any inquiries or issues related to the Pulsar PTG1022H, customers can contact Pulsar support through multiple channels․ The official website provides a dedicated support section with contact information, including phone numbers and email addresses․ Users can also utilize the live chat feature for immediate assistance․ When reaching out, it is recommended to have the product’s serial number, purchase date, and a detailed description of the issue ready․ Pulsar support can help with warranty claims, troubleshooting, and guidance on using the parts diagram PDF․ Additionally, the website offers a comprehensive FAQ section and downloadable resources, such as the PTG1022H manual, to address common questions․ For non-warranty repairs or parts replacements, customers are directed to authorized service centers listed on the official website․

Additional Resources

For further assistance, users can access the official Pulsar website for the PTG1022H parts diagram PDF․ Additional resources include online forums, tutorial videos, and authorized service centers․

8․1 Downloading the PTG1022H PDF Manual

The PTG1022H parts diagram PDF is readily available for download from Pulsar’s official website․ Users can navigate to the support section, select their model, and access the manual․ This document includes detailed diagrams, parts lists, and maintenance guides․ Additionally, it provides exploded views of components, making it easier to identify and order replacement parts․ For convenience, the PDF is searchable and printable, allowing users to reference specific sections quickly․ Ensuring you have the latest version is crucial for accuracy․ Visit the Pulsar website or authorized dealers to download the manual and access essential resources for your PTG1022H․ Regular updates may be available, so check periodically for revised versions․

8․2 Online Communities and Forums for PTG1022H Users

Online communities and forums are invaluable resources for PTG1022H users seeking advice, troubleshooting, or sharing experiences․ Platforms like Reddit forums (e․g․, r/SmallEngines or r/LawnCare) and Facebook groups dedicated to Pulsar products provide spaces for peer-to-peer support․ Users can ask questions, share maintenance tips, and learn from others who own the same model․ These communities often include DIY repair guides, part recommendations, and real-time feedback․ Additionally, specialized forums like LawnSite or ThatHomeSite cater to landscaping professionals and enthusiasts, offering expert-level advice․ Engaging with these communities can enhance your understanding of the PTG1022H and help you maximize its performance․ Always verify advice with official documentation to ensure accuracy and safety․

8․3 Authorized Service Centers and Parts Suppliers

For genuine parts and reliable service, it’s essential to rely on authorized Pulsar service centers and parts suppliers․ These centers are equipped with the expertise and tools to handle PTG1022H repairs and maintenance․ You can locate authorized service centers through Pulsar’s official website, which typically features a “Where to Buy” or “Service Locator” tool․ Additionally, Pulsar-approved parts suppliers ensure that replacements are compatible and meet quality standards․ Always verify the authenticity of suppliers to avoid counterfeit parts, which can compromise performance and safety․ Regular maintenance at authorized centers helps maintain warranty validity and ensures optimal functionality of your PTG1022H․

This comprehensive guide provides a detailed understanding of the Pulsar PTG1022H parts diagram, ensuring proper maintenance, safe usage, and long-term performance of your trimmer․ Always consult the manual for future reference․

9․1 Summary of Key Takeaways

This guide provides a comprehensive overview of the Pulsar PTG1022H parts diagram, highlighting its importance for maintenance and repair․ Key components such as the 173cc OHV engine, trimmer head, and chassis design were detailed, along with their functions․ The layout of the parts diagram was explained to help users navigate and identify components easily․ Operational manuals, safety precautions, and maintenance tips were also covered to ensure optimal performance․ Troubleshooting common issues and understanding warranty information add to the resource’s practical value․ By following this guide, users can effectively utilize the PTG1022H parts diagram for DIY repairs and routine care, extending the lifespan of their trimmer․ Proper maintenance and adherence to safety guidelines are emphasized for a seamless experience․

9․2 Encouragement for Proper Maintenance and Usage

Regular maintenance is crucial for extending the lifespan of the Pulsar PTG1022H․ By adhering to the guidelines outlined in the parts diagram and operational manual, users can ensure optimal performance and safety․ Simple practices like cleaning the air filter, checking the spark plug, and monitoring the fuel system can significantly reduce wear and tear․ Proper usage, such as avoiding excessive load and maintaining the cutting string at the recommended length, further enhances efficiency․ Users are encouraged to familiarize themselves with the parts diagram to identify and address potential issues early․ Consistent care not only prevents breakdowns but also ensures the trimmer operates at its best, providing reliable service for years to come․ Stay proactive and prioritize routine upkeep for a hassle-free experience․